Walk-in Temperature and Humidity Chamber

Specification

Temperature Specification

Temperature range:-70℃~+150℃

Temperature change range:-40℃~+90℃

Temperature fluctuation:≤±0.5℃

Temperature deviation:≤±2℃

Temperature uniformity:≤2℃(no-load)

Heating and cooling rate:1-20℃/min

Internal volume:8m³-12m³-16m³-25m³-60m³-120m³-600m³(Customizable)

Walk-in test chamber brief introduction

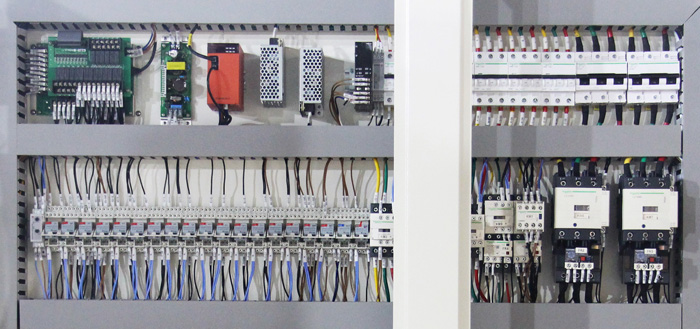

Walk-in Environmental Testing Chamber is consist of Control Panel, electrical panels, moisturizing plate blower,heater, humidifier, freezer. It provides a large spare to test the temperature and humidity for large-scale parts, semi-finished products, it applied to test products that large-scale or the quantity more, such as: computer terminals, vehicle parts.

Walk-in test chamber Product features

1. The world's first built-in USB2.0 interface, digital recorder ( can hot-swappable at any time during the records).

2. Industrial vertical full-color multi-language programmable touch control system.

3.The world's first test to be the end of the evaluation back to normal temperature protection mechanism.

4.Apply to larger size products test or large amount products test.

5.Standard modular design stainless steel plate and salt steel as the main material.

6.According to customers size and design required, we can provide them. corresponding scheme.

7. Can open the indoor. Security door and leakage circuit breaker protection device.

8. Synchronous safety control of testing power supply and safety protection device for testing products.

9. RO reverse osmosis water filter automatic water supply device for humidity using

10. Inner chamber SUS#304; Outer chamber: color steel plate material.

11. Strong and powerful German bock semi hermetic compressor.

12. Four group Server Valve, the most appropriate amount of refrigerant control.

13. Energy-saving 30%, water-saving 20%,environment-friendly refrigerant.

14. Four groups of temperature and one set of humidity sensors.

15. Heating load automatic servo control to adjust refrigerant flow rate, which can withstand the traditional constant temperature and humidity room heat load of more than 3 times.

|

Model |

ZH-080-CC-WT |

ZH-120-CC-WT |

ZH-160-CC-WT |

ZH-250-CC-WT |

ZH-340-CC-WT |

|

Interior size(W*D*H mm) |

2000*2000*2000 |

3000*2000*2000 |

4000*2000*2000 |

3000*2100*4000 |

4000*2100*4000 |

|

Outer size(W*D*H mm) |

Based on actual size |

||||

|

Temperature Range |

-70℃~+150℃ |

||||

|

Humidity Range |

20~98%R.H |

||||

|

Heating Rate |

2℃/min |

||||

|

Cooling Rate |

1℃/min |

||||

|

temperature Uniformity |

≤2 ℃ |

||||

|

Temperature Deviation |

≤±2 ℃ |

||||

|

Humidity Deviation |

≤±3% R.H(>75%RH) ; ≤±5% R.H(≤ 75%RH) |

||||

|

Temperature Fluctuation |

≤±0.5℃ |

||||

|

Temperature Resolution |

0.1℃ |

||||

|

Cooling Method |

water-cooling |

||||

|

Reference Standards |

GB/T2423.1 ; GB/T2423.2 ; GB/T2423.3 ; GB/T2423.4 ; GB/T5170.2 ; GB/T5170.5 ; GB/T11158; GB/T10589; GB/T10592; GB/T10586; IEC 60068-3-5 ; |

||||

Our services

Pre-Sales

1.Technical consultation: test method, laboratory planning and suggestion.

2.Equipment selection: selection scheme, FAQ.

3.Product testing scheme.

In-Sales

- 1.Customer communication and progress report.

- 2.Guidance for pre-installation preparation,equipment commissioning and test run.

- 3.Calibration (when Third Party's verification is required)

After-Sales

- 1.Technical training: operation of equipment, daily maintenance,common fault diagnosis and troubleshooting.

- 2.Scheduled on-site service: Detection of problem as soon as possiblein order to eliminate equipment and anthropogenic hazards. This is toensure long term and stable equipment operation as well as delivery oflatest technical information.

- 3.Technical support: special paid services are provided according tocustomer's needs.

Q1:How to get testing solution and quotation?

A1:If your product requires environmental testing, please contact us to get testing solution and quotation. We will respond to your request within

12 hours.

Q2:How to contact us?

A2:1.Phone: +886 976 590 796

2. E-mail: sales@zh-talents.com

Q3:How to place an order?

A3:If all the details of the products are confirmed,we can draft a contact to you.Also you can send the PO to us by mail.

Q4:How to deal with equipment problems and how to guarantee after-sales service?

A4:If there is problem with the equipment, please contact us and we will reply within 12 hours and arrive at your site within 48 hours.

We have after-sales service offices in Southeast Asia, Taiwan, Hong Kong and other places, and cooperative service providers in other regions.

Q5:How is the product packaged and shipped through logistics?

A5:1. Use export standard wooden boxes for packaging.

2. Choose the most favorable transportation method. Sea freight, air freight, railway, truck transportation, and multimodal transportation.

3. Fast delivery, some models are in stock and will be shipped in 1-3 days.